Optimization of Temperature Profile of billet in Extrusion Process

Microstructures in a polycrystalline material are responsible for many of its mechanical properties. In this project, the temperature profile of a cross-section of the billet is optimized to minimize the standard deviation of the grain size. This will result in a uniform grain growth. To implement this, Monte Carlo simulation based Grain Growth Package was used where a frictional heat equation solver was added. A surrogate model of initial temperature profile was created using 10 design variables and the whole system was optimized using the fmincon solver of MATLAB. Final solution results in uniform grain structure and a reduction in standard deviation from 2-4 to 0.9 units of length.

|  |

|---|---|

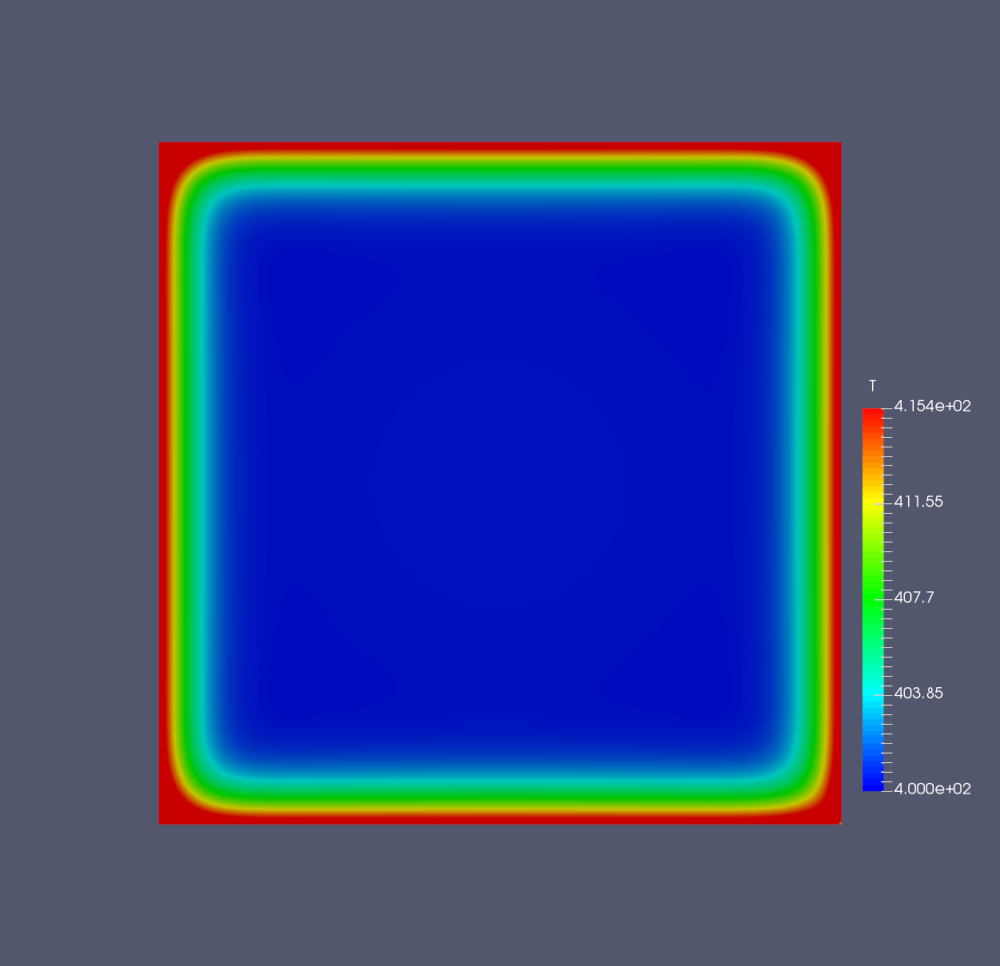

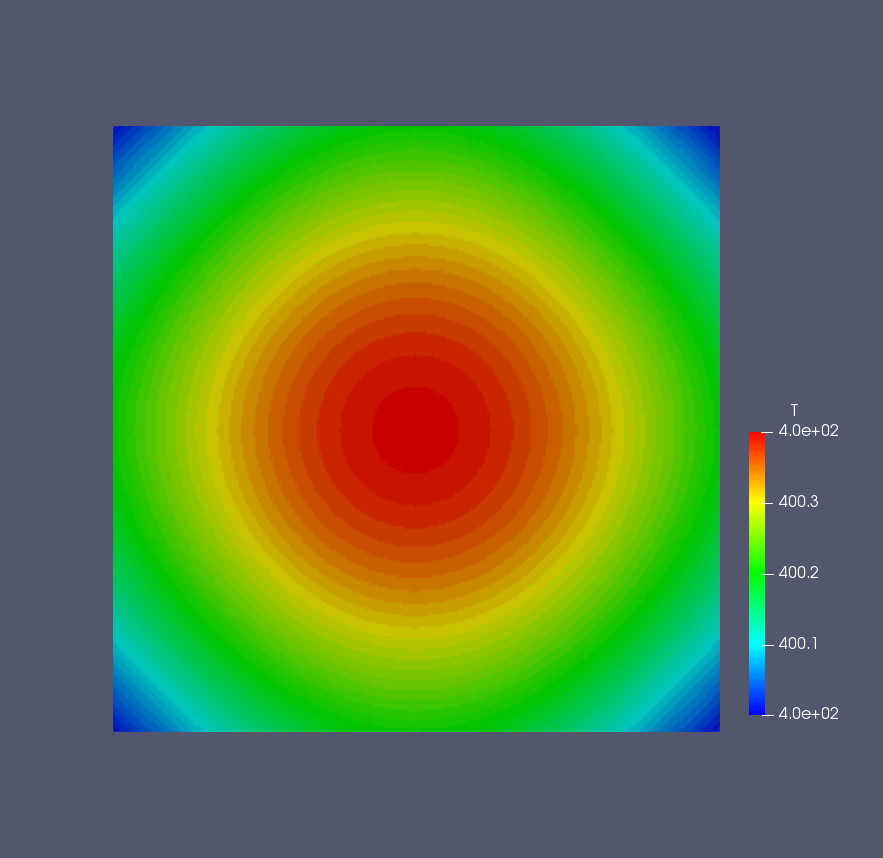

| Heat caused by extrusion process (in °C) | Optimized initial temperature field (in °C) |

|  |

|---|---|

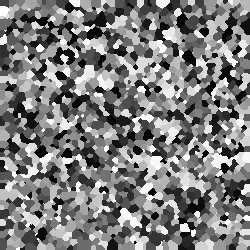

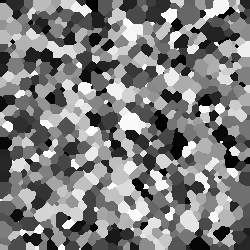

| Non-uniform grain growth caused by extrusion process | Uniform grain growth under optimized initial temperature field |